Zero-click Loadsheet

We launched cooperation with Wizz Air three years ago, promising a Loadsheet procured in less than 60 seconds. We achieved that by building a software solution with a User Interface (eXperience) fully aligned to the airline’s Ground Handling procedure—a simple, even simplistic interface requiring minimum interactions. But optimizing human interactions can only go so far. Every consecutive change brought limited return—it would not decrease the time further. The next step was connecting systems that could provide data to the “calculator” (e.g., DCS, flight schedule, EFB), eliminating redundant data input completely.

By the end of last year (i.e., 2022), we completed the integrations and secured access to all critical data. We were ready to pursue the Holy Grail—Zero-click loadsheet. Today, Evionica’s solution requires no person to be engaged to perform the computations or the documentation—the system makes the decisions autonomously. An infinite drop while comparing to the initial 60 seconds!

How does it work?

The steps described comply with Wizz Air’s Ground Handling Manual and may necessarily differ from your airline’s practices.

The steps described comply with Wizz Air’s Ground Handling Manual and may necessarily differ from your airline’s practices.

Evionica knows about upcoming flights by integrating with the airline’s scheduling system. Additionally, it receives updates on fuel estimates in accordance with the flight plan.

The system monitors the flight schedule and picks up flights with check-in closed or nearing completion—40 minutes before the departure (STD)—initiating the procedure. It will query the Departure Control System (DCS) for passengers’ numbers, seating, and bags. Bags distribute automatically—the system takes the decisions autonomously (without engagement from any personnel), adhering to a desired sequence and limitations (procedural and structural). In effect, Loading Instruction (LI/R) is being issued and delivered to the ramp (using Evionica’s Digital LI/R app). The actual handling of the turn-around begins.

At 25 minutes before STD, the Pilot in Command (PiC) should already report Final Fuel Figures (on an Electronic Flight Bag device—EFB); boarding is well underway, as well as the loading. The system will update DCS figures and compute a Preliminary Loadsheet. The Flight Crew can instantly review it on the EFB and compare it against the current flight plan.

The system is monitoring DCS for changes in flight status, awaiting the closing of boarding. Load Report should be available any minute (delivered via Digital LI/R). When both are received, it is time to issue a Final Loadsheet.

All the events may occur in a slightly different order and use various parameters. The system uses advanced heuristics to accommodate it all. Obtaining the flight-related information, utilizing the aircraft’s configuration, making all the necessary computations, and validating it proceeds autonomously, producing a Final Loadsheet without personnel’s intervention.

The formal procedure still requires an accredited person to check the Final Loadsheet (confirming its actual state) before sharing it with the PiC.

An exception to the rule

In some cases, data in digital systems (due to their intrinsic limitations) will not correspond to reality, lacking sufficient resolution or depth. E.g., payload requiring special handling, space optimizing decisions due to the non-standard volume of items, or an extra seat not being reflected in the DCS. Human Controller will have to take over and rectify the parameters using her judgment.

The status of all flights the Controller may be interested in is easily traceable in Evionica Weight&Balance software available on mobile and desktop devices.

The WAW station trial

We’ve tested it in an operational environment already! We’ve run a pilot at Warsaw Chopin Airport (WAW/EPWA).

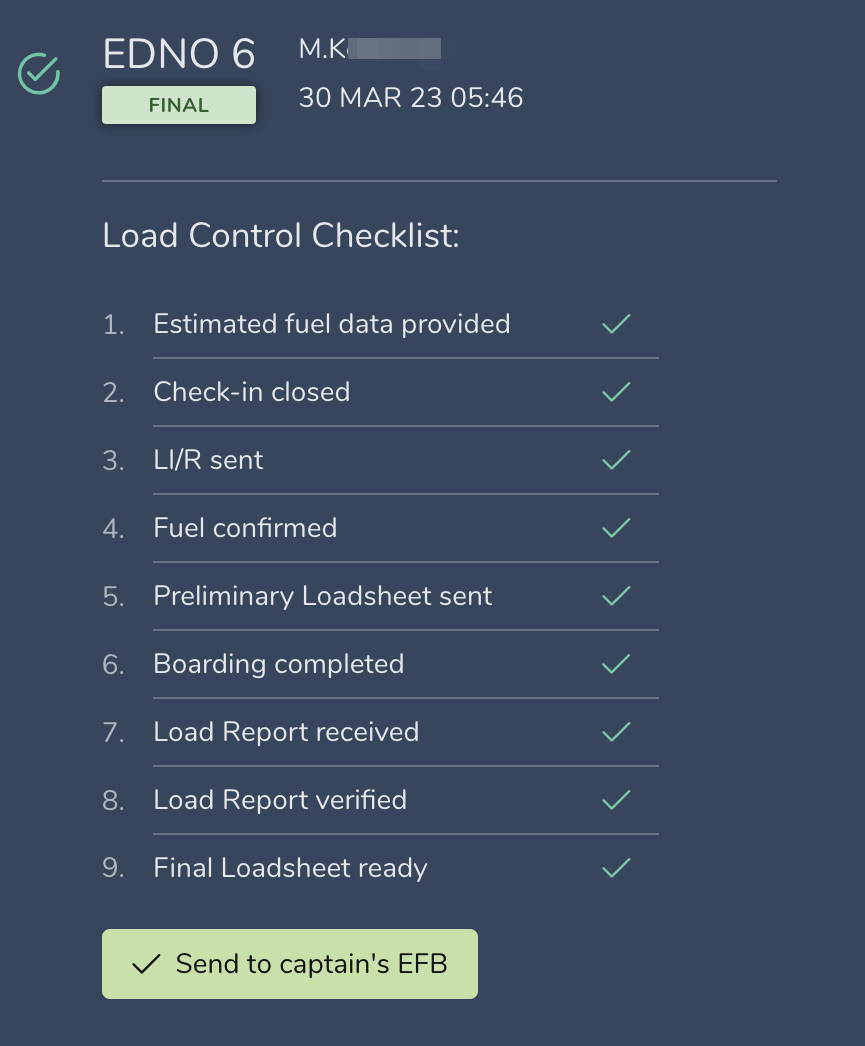

The screenshot above presents the first operational zero-click Final Loadsheet performed without human assistance (besides a required formal CHECK).

The field trial allowed us to identify operational limitations. Based on the users’ and airline’s feedback the system was fitted with several improvements (particular to Wizz’s procedure) that made it possible to achieve the goal—the zero-click Final Loadsheet—by the end of the 3-week trial period.

Introducing the Digital LI/R

Together with the Zero-click Loadsheet solution, we introduce a new mobile app digitalizing the Load Distribution reconciliation—closing the loop for a completely paperless process. The app enables the Loadmaster to fully participate in the digital process using software optimized to her needs. It facilitates an effortless review of Loading Instructions issued by the autonomous load control process. Reporting with the app does not limit to confirming the values from LI. It allows feedback with actual numbers that the system will instantly validate and apply to the computation adjusting the distribution and assuring the coherence of the Final Loadsheet with the actual loading state of the aircraft.

Algorithm’s efficacy

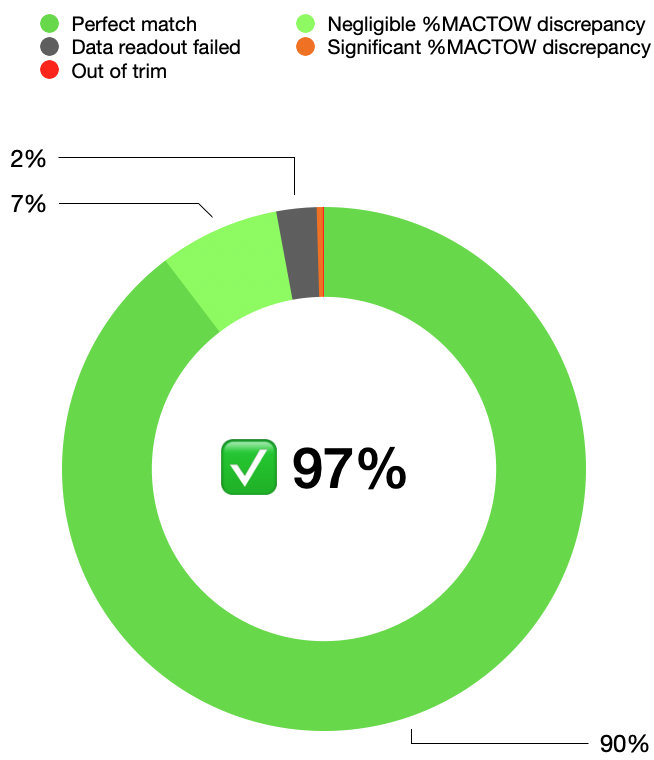

We performed a simulation to answer how effective it would be on a bigger scale. We fed the system with ~1300 recent raw flight data. We compared the outcome, the Zero-click Final Loadsheets with the original ones (performed by the Controllers).

As many as 89,65% of loadsheets were identical, applying the same strategy and procedural rigor as a human counterpart. Another 7,43% had just a slight %MACTOW difference (0,06%MAC on average), still perfectly in an envelope and inconsequential to performance.

The system failed to interpret the data correctly in just 2.48% of cases. E.g., could not handle manually declared payload, not available in DCS. In 1 case (0,08%) the system could not distribute payload—reaching close to maximum capacity—while keeping the Center of Gravity in the envelope. A significant %MACTOW discrepancy (but still well within the envelope) occurred in 5 cases (0,38%), where inaccessible hold forced alternate payload distribution. Those cases, barely 3% altogether, would trigger an exception and would require human intervention—taking over the process and rectifying associated issues.

The statistics show the solution can accomplish as many as 97% of flights autonomously—without human intervention.

Productivity and safety gains

A quick turnaround (one of the tenets of modern aviation) puts a lot of strain on the ground crew. A lot is going on! In this high pace run, there is no time to retype numbers between systems and click on a handheld device (which we know is often the case) while handling the demanding physical tasks of flight provisioning. Diligence requires focus. Evionica Weight&Balance Zero-click Loadsheet is a chance to lower the rate of incidents and enhance productivity with the automatic enforcement of the centralized Ground Handling procedure.

Simple deployment

Leveraging the newest technology (i.e., Progressive Web App, cloud computing, secure authentication, and a broad ecosystem of integrations) the software—requiring no installation—can be easily operated from any device (including mobile phone, tablet, or desktop) equipped with just a modern Web browser. No effort on the airport’s infrastructure administration team’s end is necessary.

A minimalistic user interface, strictly aligned to the airline’s procedure, lowers the learning curve remarkably, enabling user onboarding (training and certification) in less than an hour (delivered in a form of convenient e-learning).

Digital tools, available to all procedure participants, enable a truly paperless process with instant information exchange and full adherence to the airline’s standards.

Transfer of responsibility (and related costs)

The centralizing nature of the solution greatly augments the airline’s control over Load Control procedure delivery, enabling the transfer of responsibility (from Ground Handling to the airline) and reduction of related costs. A high level of automation (97%) diminishes the workload reducing requirements for a large, highly qualified (with costly accreditation) staff performing the planning and computations. The service may be executed on an exception basis requiring no effort with common operations.

Available now!

We are finalizing the development to satisfy recent feedback from the WAW trial to be ready for operational use within a month (by early May 2023).

Learn more about our solutions for passenger airlines.